How Manufacturers Prevent Air Leaks Around Window Panes

We get some wonderful questions from our customers, who often want to know more about the latest improvements in windows and window manufacturing. Recently, we received this great question regarding the steps manufacturers are taking to prevent air leaks around window panes—a common concern for any homeowner.

Dear Todd & Tod,

I know that double hung windows are only as good as the seals around them to prevent drafts and air leaks. What improvements have manufacturers made lately to create better seals and prevent air leaks around window panes?

–Edward

First of all, we want to thank Edward for this excellent question! Here in Wisconsin, air infiltration around windows in your home is a big problem, especially in cold weather.

At Weather Tight, we have over 35 years of experience battling these cold winter months. During that time, we’ve seen many changes and improvements in window manufacturing. Here’s how manufacturers are designing better seals to prevent air leaks around window panes.

What’s So Bad About Air Leaks Around Window Panes?

We all know windows are designed to keep the warm air inside and to keep the cold air out during the winter time. Without proper sealing solutions, the windows become less effective. Cold air seeps into your home and can greatly impact your comfort and wellbeing.

Air leaks are a huge worry and expense for homeowners. Much of the heat loss in your home stems from drafty windows (as well as through a roof that may need a replacement) and as the heat goes out and cold comes in, your energy bill continues to skyrocket. This not only means extra blankets and socks when you’re watching a movie on the couch, but it means spending extra money to heat your home as you turn up the thermostat.

Here in the Midwest, we often see homeowners getting out the plastic and tape to prevent dreaded window drafts in the winter. There are a number of reasons why plastic on the windows isn’t an effective or long-term solution. If you can feel the cold air leaking around your window panes, chances are you need window replacement, not plastic and tape!

Of course, the question on every homeowner’s mind is: are new windows really worth the investment? If manufacturers aren’t taking steps to improve the seals and design of the windows, are you doomed to replace them every decade as the seals wear out?

The good news is that over the last decade, window manufacturers have made huge improvements in airtight features of their windows. Today, windows hold up to cold weather and keep your house safe and comfortable for years to come. Here’s what manufacturers are doing to ensure your new windows will prevent air leaks around window panes.

Improvement in Modern Window Seals and Design

There is a great deal of new technology used in window seals and design. Even in the last 10-15 years, great strides have been made to prevent air loss around window panes. Older homes and even homes built in the last few decades may need window replacement, especially if the original window panes were made with materials like aluminum, wood, or steel.

With these improved window sealing and design features, you can rest assured that your new windows will remain tightly sealed for years and years to come. Here are the best features in new windows to prevent air leaks around window panes.

Quality Weatherstripping

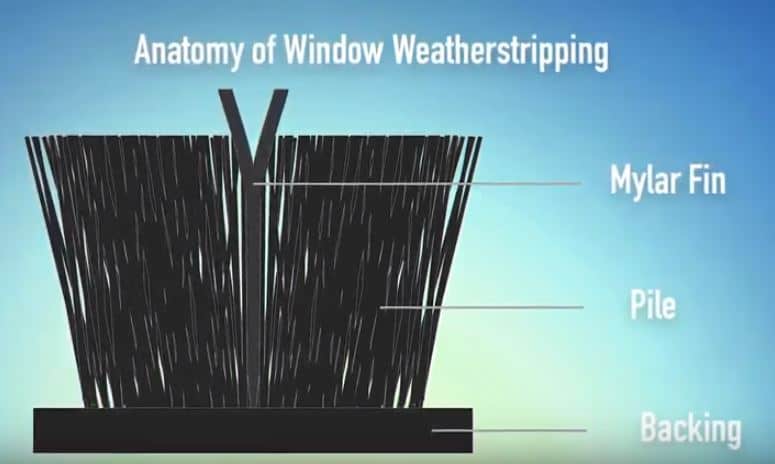

If you’re concerned about air leaks around your current windows, the first step is to check the weather-stripping. The stripping should be in good condition, not folded down or damaged. Stripping should run all the way around the perimeter of the window, as well as across the center.

Most weatherstripping features a raised point or “fin” in the middle of the strip. This is called the Mylar fin. It makes the stripping stand up stronger and taller as it compresses against the window frame. This Mylar fin is key in helping to prevent air leaks around window panes, keeping the window airtight.

These days, window manufacturers are using double and even triple weather-stripping for the lowest air infiltration rates. Weather Tight replacement windows, such as our full-frame windows, feature this unsurpassed air leak prevention. The more weather stripping the manufacturers use, the better off your window will be in terms of air leaks and air infiltration.

Bottom of the Window Sealing

If you look along the bottom of most new windows, you’ll see what’s called a bulb seal. This is a rounded rubber seal that keeps the window tightly sealed and prevents air leakage. This seal should also be in excellent condition—free of cracks or damage. If your bulb seal isn’t in good shape, this can often be the source of window air leakage.

Think of the window’s bulb seal as being similar to the seal around your refrigerator and freezer door. It keeps cold air from leaking out of the fridge and ensures your food stays a consistent temperature. Similarly, the bulb seal keeps your home at a consistent temperature and prevents air from getting in and out under the window.

Many new windows now feature a double seal. While one seal is good, two is, of course, better. When you close your window, the cold air is completely sealed out, allowing almost nothing in across the bottom and side of the window. This keeps your home warm and comfortable in the cold months when your windows are closed.

Special Tapered Locks

Older homes may feature windows with simple metal locks and even clamps, screw-in, and squeeze-locks that keep the window shut and locked.

While these locks are an important security feature that prevents the window from being opened from the outside, they don’t effectively seal the window and prevent air leaks around window panes. They can also be difficult to open in an emergency situation (or for simply cleaning the window).

Newer windows, however, feature special tapered locks. When you close the window and lock it, the window sashes are tightly squeezed together. This tight closure holds the weather stripping exactly where it needs to be to stop air leaks and cold air from sneaking through.

Strong Fiberglass Frames

We think of windows as solid structures that don’t move at all. The truth is, when the wind blows hard against window frames, they can bow and move. This is called deflection and it happens in almost all homes.

When this occurs, the movement and pressure alters the window frame, which can eventually become loose. The weather stripping will then no longer create an effective seal against the window and window pane and unfortunately, you will start to see some air infiltration.

Newer replacement windows remedy this problem by using a number of reinforcement materials. Some are made of wood, aluminum, or steel. None of these materials are nearly as effective as fiberglass, which has the tensile strength of steel but is a non-conductive material (which is why fiberglass is also used in home insulation).

With non-conductive fiberglass, the cold won’t seep in through the window frame and get into your home. Fiberglass also prevents the sash from misshaping and stays strong in all types of weather. This is a cutting-edge solution for strong, airtight windows.

So, if you’re experiencing air infiltration with your windows, take the plastic off your winter prep list. Chances are, it’s time to look at installing replacement windows to prevent air leaks around window panes.

If you’re ready to install new windows and improve the comfort, livability, and look of your home, Weather Tight is here to help! Contact us today and we’ll talk you through the process. We’re happy to visit your home and assess the effectiveness of your windows. Call us today to learn how affordable new windows can be. You’ll save the discomfort and high energy bills that come with leaky windows in the winter.

414-459-3874

414-459-3874

Text Us!

Text Us!